Application Scenarios

Power Industry (DC panels in substations, relay protection devices).

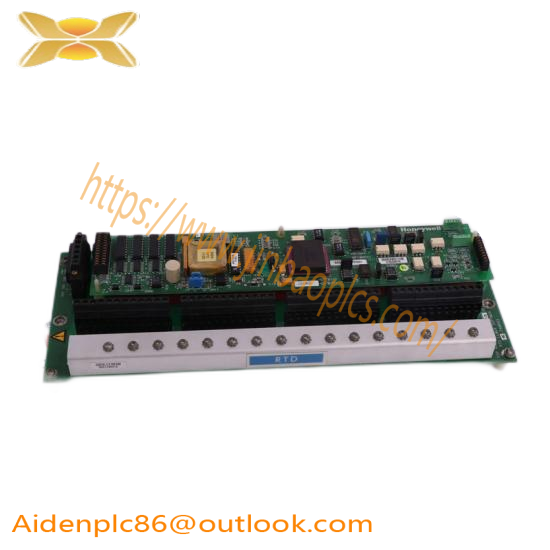

Industrial Automation (PLC control systems, DCS distributed control systems).

Rail Transit (signaling systems, communication equipment power supplies).

New Energy (auxiliary power supplies for photovoltaic inverters, control power supplies for energy storage systems).

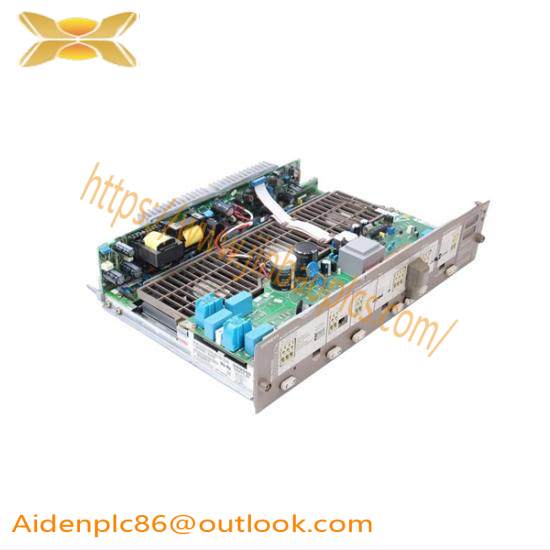

Core Functions

DC Power Conversion

Converts AC input (e.g., 220V AC) into stable DC output (commonly 24V DC or 48V DC).

Supports a wide input voltage range (e.g., 85-264V AC) to adapt to diverse power grid environments.

High Reliability Design

Redundancy Support: Multiple modules can be connected in parallel to achieve N+1 redundancy, eliminating single points of failure.

Hot-Swap Function: Supports hot-swappable module replacement, reducing system downtime.

High MTBF (Mean Time Between Failures): Industrial-grade design with a lifespan of over 10 years.

Comprehensive Protection Mechanism

Overvoltage Protection (OVP), Overcurrent Protection (OCP), Short Circuit Protection (SCP), and Overtemperature Protection (OTP).

Input undervoltage/overvoltage protection prevents power failure and damage to the device.

Intelligent Monitoring and Communication

Built-in monitoring module displays voltage, current, temperature, and other parameters in real time.

Supports communication protocols such as Modbus RTU/TCP and Profibus, allowing connection to host systems (such as SCADA).

Product Features

High-Frequency Switching Technology

Soft switching technology reduces switching losses and improves efficiency by 10%-15%.

A 30%-50% smaller size and lighter weight facilitate integration into control cabinets.

Digital Control

Based on a DSP (digital signal processor), it achieves precise voltage regulation and fast protection response (response time <10μs).

Remote firmware upgrades extend product lifecycle.

Electromagnetic Compatibility (EMC) Optimization

Compliant with IEC 61000 standards, it offers strong anti-interference capabilities and is suitable for complex electromagnetic environments (such as substations and factory floors).

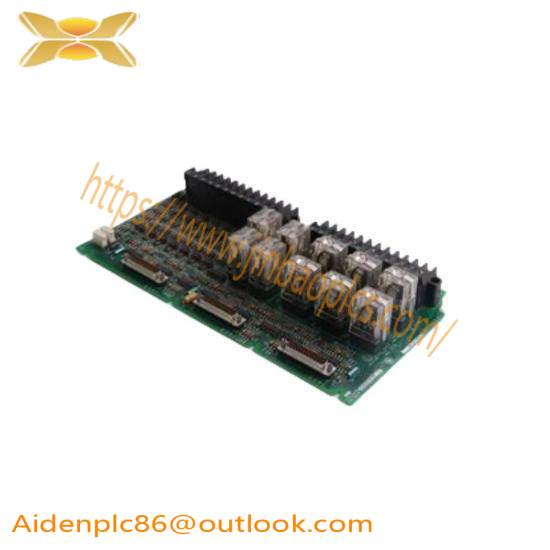

Modular Design

Standardized interfaces facilitate quick installation and maintenance.

Interchangeable with other ABB power modules (such as the PSD series).

Selection and Adaptation Guide

Confirm Load Requirements

Calculate the total load power (W) and select a module with an output power ≥ 1.2 times the load requirement.

Example: If the total load power is 400W, a 600W module (such as the 600W version of the 3BSE003832R1 ) is recommended.

Input Condition Compatibility

Confirm that the input voltage range covers site power fluctuations (for example, the fluctuation range of the Chinese power grid is typically ±10%).

Check the frequency requirements (50Hz or 60Hz).

Environmental Adaptability

The operating temperature range must cover the site environment (for example, in cold northern regions, confirm low-temperature startup capability).

Protection level options: IP20 (indoor) or IP54 (dustproof and waterproof, suitable for outdoor cabinets).

Redundancy and Scalability

For high reliability, select a model that supports parallel redundancy (e.g., configuring two modules for 1+1 redundancy).

Reserved expansion slots allow for future module additions.

Installation and Commissioning

Installation Key Points

Mechanical Installation: Secure to a standard DIN rail or control cabinet, ensuring adequate ventilation.

Electrical Connections:

Connect the input to an AC power source (L/N/PE).

Connect the output to a DC load (positive/negative).

Connect the communication interface (e.g., RS485) to a host computer.

Grounding: Ensure the PE terminal is reliably grounded in accordance with IEC 60364.

Commissioning Steps

Pre-power-on Check: Confirm that the input/output voltage settings are correct and that there are no short circuits in the wiring.

Power-on Test: Observe the module indicator lights (green for normal operation, red for fault).

Parameter Configuration: Set output voltage, protection threshold, etc. through the host computer software.

Maintenance and Troubleshooting

Daily Inspection

Check whether the input/output voltage is normal (measure with a multimeter).

Check whether the cooling fan is running and whether the vents are blocked.

Check the status of the alarm indicator (a red light indicates a fault).

Common Faults and Solutions: Symptoms, Possible Causes, and Solutions

No output: Input power not connected, fuse blown. Check the input power supply and replace the fuse (e.g., 2A/250V).

Unstable output voltage: Load overload, capacitor aging. Reduce the load and replace the output capacitor (e.g., 1000μF/35V).

Overheating shutdown: Poor ventilation, high ambient temperature. Clean the dust screen and improve ventilation.

Communication Fault: Loose communication cable, incorrect address setting. Check the cable connection and reconfigure the communication address.

Regular Maintenance

Check the capacitor status every six months (e.g., whether the ESR value is elevated).

Replace the cooling fan bearing lubricant annually.

Related product recommendations:

3BHB004692R0002

3BHB004693R0001

5SHY35L4503

AO810

3BSE050091R65

PFEA112-65 3BSE050091R65

PCD235B1101 3BHE032025R1101

CI810B 3BSE020520R1

SD822 3BSC610038R1

More…

There are no reviews yet.