Electrical parameters

Working voltage: flexibly adapt to 24V DC, 120V AC or 220-380V AC to meet the needs of different industrial scenarios.

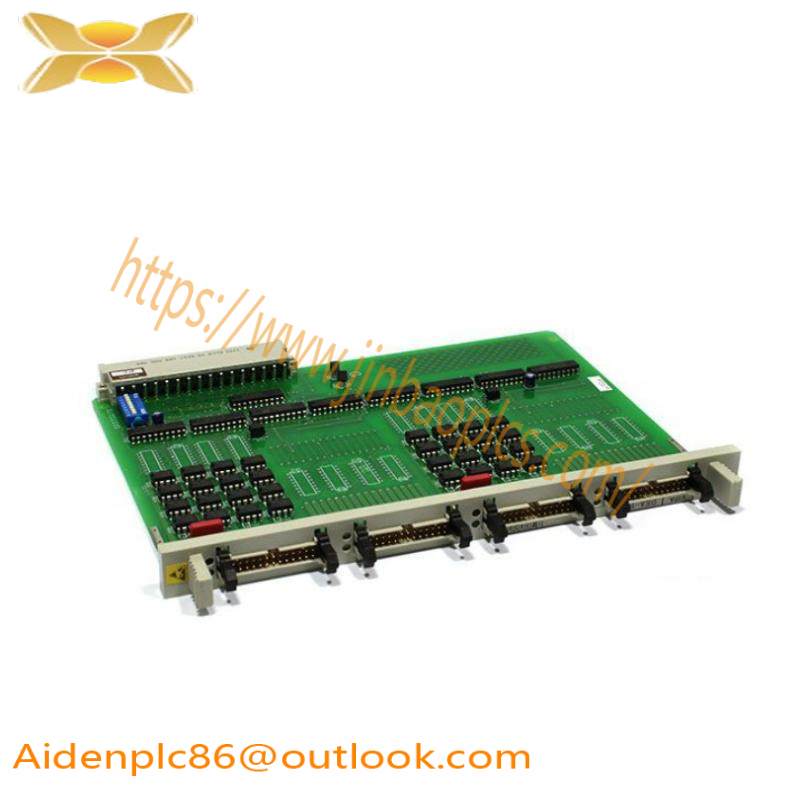

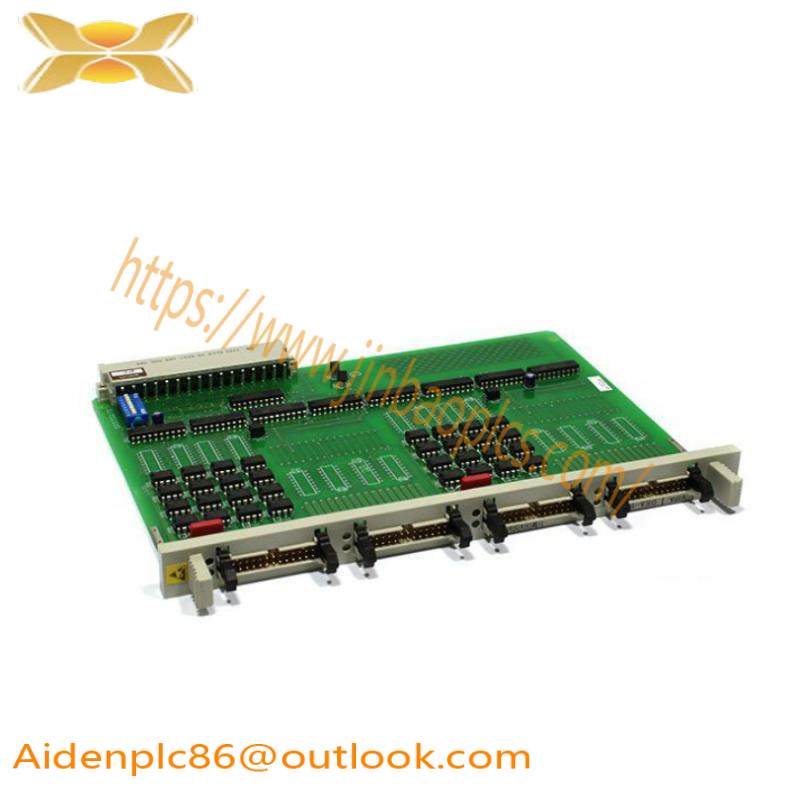

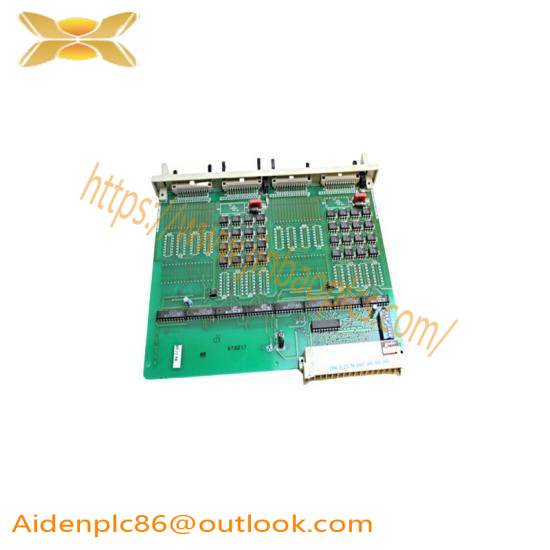

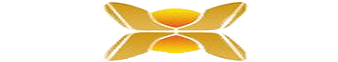

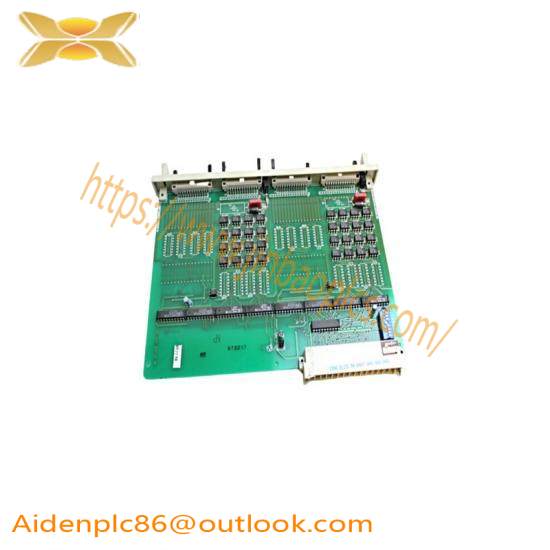

Input/output channels:

Binary input module (BIM): provides 16 input channels (some models support pulse counting function).

Binary output module (BOM): configured with 12 groups of 24 relay output channels, supporting large current capacity (such as 10 output channels divided into 3 groups, including 2 high-speed relays).

Physical size: The packaging size is about 110mm×106mm×20mm, and the weight is about 1.2kg, which is easy to integrate into a compact control cabinet.

Communication interface

Support industrial standard protocols: Modbus, PROFIBUS, Ethernet/IP, etc., to ensure seamless connection with multi-brand equipment.

Expansion capability: The communication function can be expanded through the F series communication module, but it should be noted that some IO points will be reduced.

Core functional characteristics

Anti-interference and stability

Strong anti-electromagnetic interference capability: meets industrial environment standards and can operate stably under extreme conditions.

Local timestamp and signal identification: each IO event is accompanied by a timestamp, supports software identification of oscillation signals, and improves fault diagnosis efficiency.

Input/output optimization

Battery ground fault tolerance: even if the battery power supply grounds fault, the input signal can still work normally to ensure system continuity.

Large current output support: binary output modules support high load requirements such as trip output or signal control.

Flexible configuration

Modular design: BIM (input) or BOM (output) modules can be selected according to needs, or mixed.

High-speed signal channel: some models provide dedicated high-speed relay output, suitable for scenarios with high response speed requirements such as time synchronization.

Typical application scenarios

Process control industry

Chemical/petroleum: used for key links such as reactor temperature control and pipeline pressure monitoring.

Electric power/metallurgy: realize generator set status monitoring and blast furnace automation control.

Manufacturing Automation

Production Line Control: Integrate into PLC system to manage the collaborative operation of robots, conveyor belts and other equipment.

Equipment Monitoring: Collect sensor data in real time through analog input channels to optimize production processes.

Energy and Building Management

Power System: Used for substation automation and power quality monitoring.

Smart Building: Control lighting and air conditioning systems to achieve a balance between energy saving and comfort.

Compatibility and Scalability

Multi-protocol Support

Compatible with mainstream protocols such as Modbus, PROFIBUS, Ethernet/IP, and can be networked with brand equipment such as Siemens and Schneider.

Optional Expansion

BIO-01 Board: Add 3 DI, 1 DO and 1 AI input to make up for the reduction of IO points caused by F series communication modules.

RAIO-01 Module: Expand analog output channels and support 0-20mA/4-20mA signals.

System Integration

It belongs to the ABB AC500 series PLC ecosystem and can work with DCS50 inverters, GFD563A controllers, etc. to build a complete automation solution.

Summary

The ABB 1MRB150022R0002 communication module is widely used in key areas of industrial automation with its core advantages of high reliability, strong anti-interference and flexible configuration. Its modular design and multi-protocol support enable it to adapt to complex industrial environments, making it an ideal choice for improving production efficiency and system stability.

Related product recommendations:

S-113H 3BHB018008R0003

3BHB018008R0003

3BHB009884R00211

S-073N 3BHB009884R00211

S-123H 3BHB030479R0512

3BHB030479R0512

DP640 3BHT300057R1

3BHT300057R1

S-093M 3BHB009885R0013

3BHB009885R0013

S-097H 3BHB009885R0052

3BHB009885R0052

S-093M 3BHB009885R0063

3BHB009885R0063

S-093H 3BHB009885R0005

3BHB009885R0005

More…

There are no reviews yet.