Sensor Type:Vibration

Sensing Range:0.01 mm – 10 mm

Sensitivity:0.001 μm

Output Type:4-20 mA Analog Output

Installation Type:Non-contact

Operating Temperature:-40°C to +125°C

Package/Casing:Robust Injection Molding

Material:Stainless Steel

Characteristics:[“High Sensitivity”,”Corrosion Resistance”,”Shock and Vibration Resistant”]

Termination Type:Gold-plated Connector

Applicability:Ideal for Motor, Pump, Turbine Maintenance

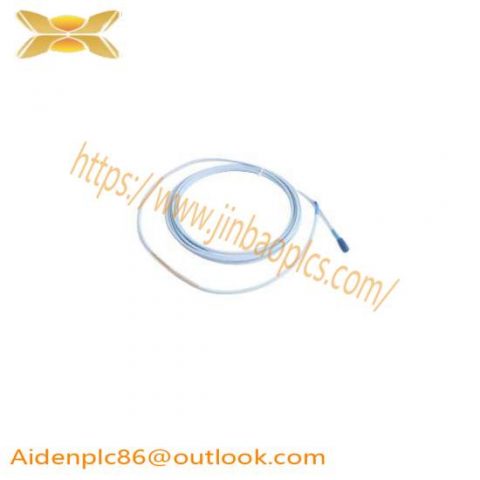

Introducing the Bently Nevada 330101-00-08-05-02-05 Vibration Sensor, the ultimate choice for precise machinery health monitoring. This sensor is meticulously engineered to provide unparalleled accuracy in detecting even the slightest changes in vibration patterns, enabling proactive maintenance and minimizing downtime.

Crafted from premium stainless steel, our sensor ensures durability and resistance to harsh industrial environments. Its robust injection molding casing offers protection against external impacts and corrosion, guaranteeing consistent performance over time.

Experience enhanced monitoring capabilities with our sensor’s advanced output technology. The 4-20 mA analog output ensures seamless integration with existing control systems, facilitating easy data interpretation and analysis.

The non-contact installation feature allows for safe and efficient deployment, reducing the risk of equipment damage during setup. Additionally, its wide operating temperature range (-40°C to +125°C) makes it suitable for a variety of industrial settings, ensuring reliable operation across different climates and conditions.

Equipped with gold-plated connectors, our sensor ensures stable and reliable signal transmission. This feature is crucial in maintaining high-quality data integrity, essential for accurate vibration analysis.

Designed for motor, pump, and turbine maintenance, this vibration sensor plays a pivotal role in predictive maintenance strategies, helping industries to anticipate potential failures and optimize operational efficiency.

There are no reviews yet.