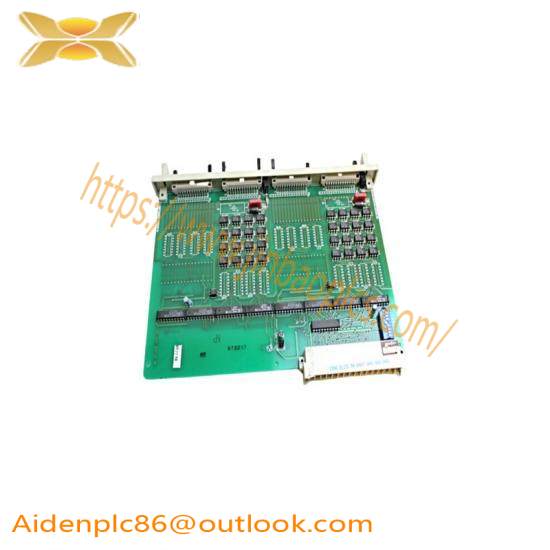

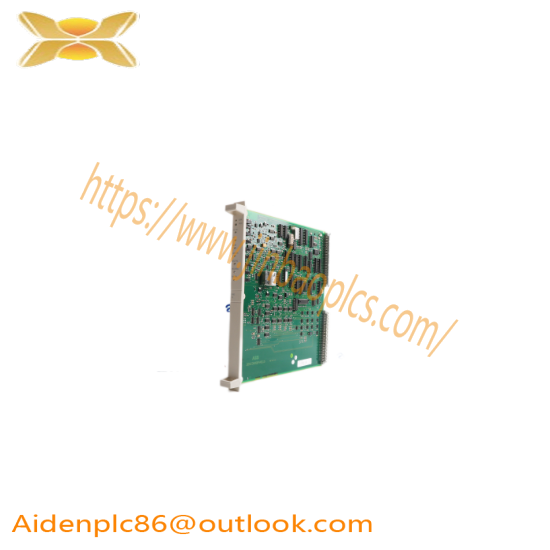

NSSM01 is a high-reliability industrial communication module launched by ABB. It is a key component in the automation control system and is mainly used to realize data exchange between PLC/DCS controller and field equipment, host computer or other controllers.

Protocol conversion: supports multiple industrial communication protocols (such as PROFIBUS-DP, Modbus RTU/TCP, EtherCAT, etc.) to achieve interconnection between different devices.

Data transmission: provides high-speed and stable real-time data channels to ensure the timeliness of control instructions and status feedback.

Network expansion: access the industrial bus as a master or slave station, expand the system I/O points or connect remote devices.

Technical specifications and features

1. Communication protocol support

Mainstream protocols:

PROFIBUS-DP: suitable for field-level communication of PLCs such as Siemens and ABB, with a maximum transmission rate of 12Mbps and support for 32 slaves.

Modbus RTU/TCP: Strong compatibility, widely used in HMI, sensors, inverters and other equipment, supports serial port (RS-485) or Ethernet (10/100Mbps).

EtherCAT: Real-time Ethernet protocol, cycle time <100μs, suitable for high-speed motion control scenarios (such as robots, packaging machinery).

Other protocols (configured by model):

DeviceNet, CANopen, CC-Link, etc., to meet specific industry needs (such as automobile manufacturing, semiconductor equipment).

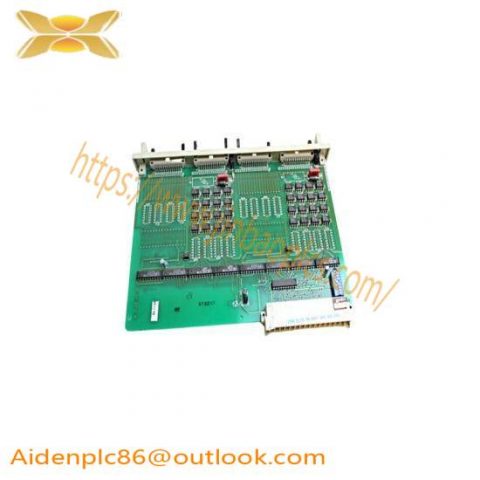

2. Hardware design

Interface type:

PROFIBUS-DP: DB9 pin connector, supports bus power supply (optional).

Ethernet: RJ45 interface, supports MDI/MDI-X automatic crossover, compatible with standard network cables.

Serial port: RS-485 (Modbus RTU), with terminal resistor jumper, strong anti-interference ability.

Electrical isolation:

The isolation voltage between the communication interface and the internal circuit of the module is ≥1500V AC to prevent damage to the equipment by lightning strikes or ground faults.

Environmental adaptability:

Working temperature: -20℃~70℃ (industrial grade), some models support -40℃~85℃ (wide temperature type).

Protection level: IP20 (rack installation), optional IP65 (field installation type).

3. Diagnosis and maintenance

LED indicator:

Power: power status (green/red).

Status: module operating status (flashing = normal, always on = fault).

Comm: communication activity (flashing yellow light = data transmission).

Diagnostic tools:

Monitor bus traffic and error frame count through ABB Engineering Tool or third-party software (such as Wireshark).

Support SNMP protocol and integrate into factory-level network management systems (such as ABB Ability™ EdgeInsight).

Typical application scenarios

1. Factory automation

Production line integration: connect PLC, HMI, inverter, sensor and other equipment to achieve data sharing and collaborative control (such as automotive welding line, food packaging line).

Remote I/O: expand I/O points through EtherCAT or PROFIBUS-DP to reduce long-distance wiring costs (such as petrochemical plant tank area monitoring).

Redundant communication: configure dual module hot standby to ensure zero interruption of communication for key systems (such as nuclear power plant control).

2. Energy management

Smart grid: connect smart meters, circuit breakers, photovoltaic inverters to achieve real-time monitoring and scheduling of distributed energy.

Building automation: integrate air conditioning, lighting, security systems, optimize energy consumption (such as reading meter data and adjusting fan speed through Modbus TCP).

3. Process control

Chemical industry: connect reactor temperature sensors, flow meters, valve positioners to achieve closed-loop control (such as PID adjustment).

Water treatment: Connect PLC and SCADA system through PROFIBUS-DP, monitor water quality parameters (such as pH value, turbidity) and automatically add medicine.

Installation and commissioning steps

1. Mechanical installation

Rack fixing:

Use standard DIN rail (35mm width) and firmly install it through the bottom buckle of the module. The screw torque is recommended to be 0.5-0.6N·m.

Keep at least 10mm gap between modules for heat dissipation and maintenance.

Grounding treatment:

The module shell is grounded through shielded wire, and the grounding resistance is <1Ω to prevent static electricity or lightning from damaging the communication interface.

2. Electrical wiring

PROFIBUS-DP connection:

The master station and the slave station are connected by A/B line pairs, and the terminal resistor (120Ω) is connected to both ends of the bus.

Avoid parallel wiring with power cables, the distance is >30cm or use shielded cables.

Ethernet connection:

Use Category 5e or Category 6 network cable, support 100m transmission distance (no relay).

Avoid conflicts with other devices in the network when configuring IP address (such as the master system IP range 192.168.1.x).

Serial port connection:

Modbus RTU uses RS-485 half-duplex communication, and A/B lines need to be cross-connected (master station A connects to slave station B, master station B connects to slave station A).

Set the terminal resistor jumper to the “ON” position (only the devices at both ends of the bus need to be set).

3. Software configuration

Address setting:

PROFIBUS-DP: Assign slave address (range 0-125) through DIP switch or master system software (such as STEP 7).

Modbus TCP: Set IP address, subnet mask, port number (default 502) in the module Web interface.

Parameter download:

Use ABB Engineering Tool or GSD file (PROFIBUS-DP) to import module configuration, set communication rate and data format (such as 8N1).

Verify that communication parameters (such as baud rate and check bit) are consistent with those of slave devices to avoid communication failure caused by protocol mismatch.

Logic programming:

Write communication instructions in the master control system (such as “SFC14/15” of Siemens S7 for PROFIBUS-DP data reading and writing).

Test communication function: Send test instructions through HMI or diagnostic tools to confirm that the module can correctly receive/send data.

Summary

The ABB NSSM01 communication unit has become a core component in the field of industrial automation communication with its multi-protocol support, high reliability and flexible configuration. Users need to accurately select according to protocol compatibility, performance requirements, and environmental conditions, and strictly follow the installation and commissioning specifications to give full play to its performance advantages.

There are no reviews yet.